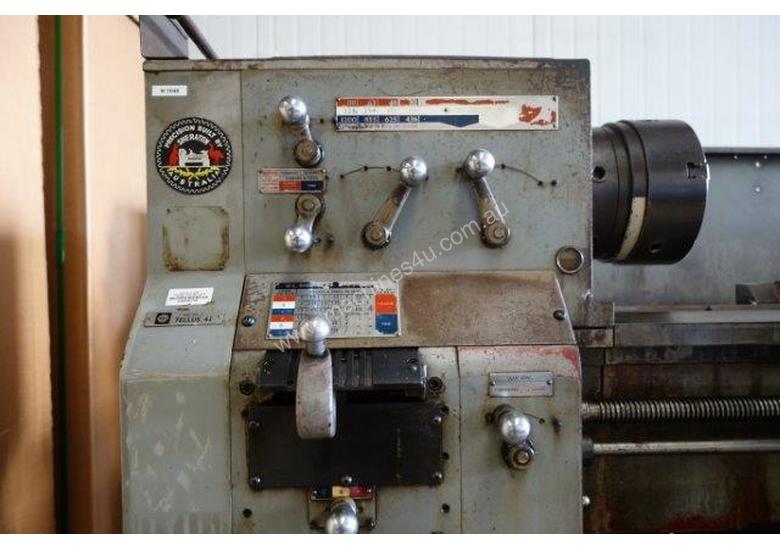

If you have any comments regarding this manual, please write to us at the address below: Grizzly Industrial, Inc. C/ O Technical Documentation Manager P.O. Box 2069 Bellingham, WA Email: manuals@grizzly.com Contact Info The primary purpose of the metal lathe is to make concentric cuts in metal stock. Got the old Hercus Lathe cleaned up, oiled and running. The halfnuts are worn right out, but everything else seems to be in good shape, just very dirty. Next is to detail the old girl.

Sheraton '9-Inch' lathe. The very best Manual is the one produced in England for the South Bend clone made by Boxford. Unlike the South Bend book 'How to Run a Lathe' this 170-page edition concentrates in detail on the 9-inch lathe. I have also added all the known relevant South Bend 9-inch data to give a complete data pack for the machine: operating instructions - extra comprehensive screwcutting charts with metric conversions for both the changewheel and gearbox models and other valuable data.

SHERATON Cub, Cadet, Diploma and Defiance lathes. These lathes were mechanical copies of the LeBlond and 'LeBlond Makino' lathes as made from the 1950s to 1980s. Supplied for these Sheraton lathes is a copy of the detailed and well-illustrated Instruction, Maintenance & Illustrated Parts Manual as detailed Cross-Sectional Drawings as published by LeBlond, not Sheraton. Instead of the various models being accorded a Model Type by size, as per the LeBlond system. Sheraton gave them individual names: Cub, Cadet, Diploma and Defiance.

| High quality new machinery |

- BNC/CNC Flat Bed Lathes

- LT/HT Slant Bed Lathes

Sheraton Challenger Lathe Manual Parts

- Table Type HBM

- Floor Type HBM

- Ram Type HBM

|

Sheraton Challenger Lathe Manual Gearbox

| Home|CNC Lathes|CNC Boring Mills|CNC Machining Centers|Contact Us |

| 10 Industrial Highway, Lester, PA 19113 | Phone: (631) 249-5566 |sales@challengermachinetools.com Copyright 2014 Challenger Machine Tools LLC. All Rights Reserved. |